Frequently Asked Questions

Who are you working for?

For you, for designers and agencies, for large offset printing companies, for companies in the paper industry, for production agencies for brand products company, for professionals, for artists and gallery owners, for start-ups and sometimes for ourselves.

What’s your turn-around time?

For most jobs, we estimate ten to fourteen working days (Mon-Fri, without holidays). Some more complicated jobs (multiple printing processes, hotfoil stamping, die cutting etc.) may require a longer lead time. Rush jobs are possible by precise scheduling and an additional rush fee. The clock starts ticking when your data is ok and everything is approved by you, or your client.

What is the cost of letterpress?

Most of our work is personalized and custom made, so there is no such thing as a simple price list. We do however, have a price list for standard business cards.

Letterpress printing is considerably more costly than offset printing, due to the custom, hand made nature and materials employed.

Can I stop by for a press check?

Absolutely, please make an appointment.

What is a proof/press proof?

We create a small run on a hand cranked proof press, before your job goes on the production machine, to ensure everything is correct. Ideally, you’d sign off on the proof. FOr smaller jobs we provide a digital pdf proof for review.

Would you be able to make short runs, say, an edition of 25?

Yes, we do short runs quite frequently, as we have the capability to create negatives and photopolymer plates in house.

What size run / edition is most economical?

For a reasonable quantity/cost ratio, we’d recommend a run of 250 to 500 copies (small-format stationery, such as business cards) from our perspective. We run an edition of 250 business cards one-up, 500 two-up, and 1,000 four-up… in essence an edition of 250 is the sweet spot for us.

Can you print very large runs?

Larger runs – for example, 100,000 product labels, say, for a fashion brand – are feasible, yet not necessarily economical. We can certainly talk about your large run project.

Is it possible to letterpress without the deboss?

Printing and debossing is a singular process, hence the absence of imprint does not lead to a reduction in expense. Generally Letterpress is possible without, or with a reduced debossing effect, we’d call this a kiss impression. An offset-like appearance of text and lines can usually be achieved. Looking through a loupe, however, will always show a slight debossing effect.

Is it possible to deboss only certain areas?

Yes, it’s possible if the elements have enough space between each other. If they are very close together, or even overlap, this effect can only be achieved by running the sheet multiple times with separate plates, which will increase cost.

Can you letterpress photographic images?

Letterpress works best for typography, illustrations, line art, etc. Halftoning/screening images is possible, but would not give you the results you’d get from offset lithography. However, coarse halftones as a graphic design element can look quite rad. Sometimes it just makes sense to combine various printing methods…

Can you print white ink on black paper?

Letterpress’d opaque white looks quite underwhelming, and we’d suggest silk screen printing for opaque colors on dark stock. We could achieve the deboss effect with a second run through one of our letterpress machines. Hot foil stamping is also an alternative, if you’re looking for a shiny impression.

What colors do you letterpress?

We have the ability to mix every color that’s included in the Pantone Uncoated Plus System, in addition to that we have PMS metallic and fluorescent inks.

Are you able to print multi-color jobs?

Multi color jobs require multiple runs, which greatly increases time and effort, 1-color and 2-color jobs hit the sweet spot for letterpress printing.

Our ink is highly pigmented and — as with offset inks — translucent, so you always work with subtractive color in case of over-printing areas.

How many colors can you print in one job?

Most letterpress jobs are being printed with less than four different colors, since the number of colors multiplies the setup effort.

What about silver, gold or other metallic colors?

Metallic colors, such as Pantone 872 gold or 877 silver are possible, and work a-ok on uncoated papers. The metallics are not as shiny as hot foil stamping, or even silk screening, but in some cases, this may be desirable. Metallics have pretty good coverage on darker stock, so that’s an option to keep in mind.

Can you print halftones?

With letterpress, we have limited use of halftones and would suggest, to use coarse screens as a stylistic element.

Can you print glossy, or do UV coating?

While technically it’s possible to print on coated papers — No, we simply don’t letterpress on coated paper, and we’d have to employ different printing methods to achieve this.

Can I work with the Pantone Coated system?

No, we strictly print on uncoated papers, and work with Pantone Plus Uncoated inks.

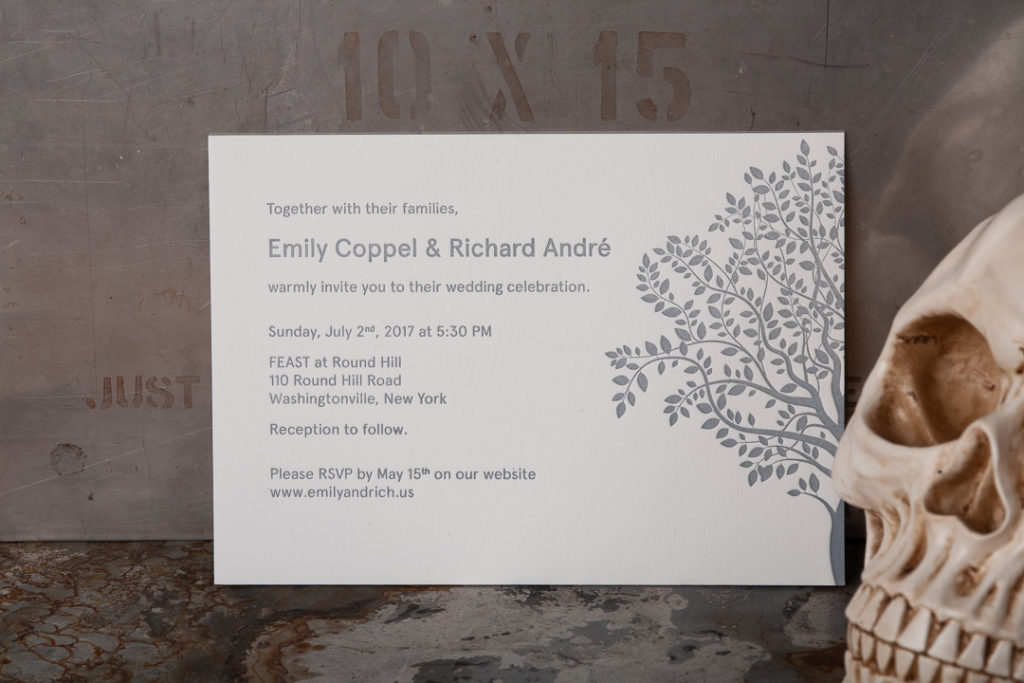

What is a blind impression?

It’s a letterpress imprint, printed without ink.

What is blind embossing?

A blind emboss, the printed parts are raised on the stock, exactly the opposite of a deboss. Please make sure to communicate exactly what you’re looking for.

Can I align my environmental conscience with your process?

We use almost no chemicals in our shop. Letterpress printing is very economical and environmentally friendly, as it uses very little ink — a one pound can of ink goes a long, long way — and small runs may use as little as a teaspoon of rubber based ink. We clean our tools with recycled cotton rags and mineral spirits or vegetable oil. Our photopolymer plates get washed out with plain tap water.

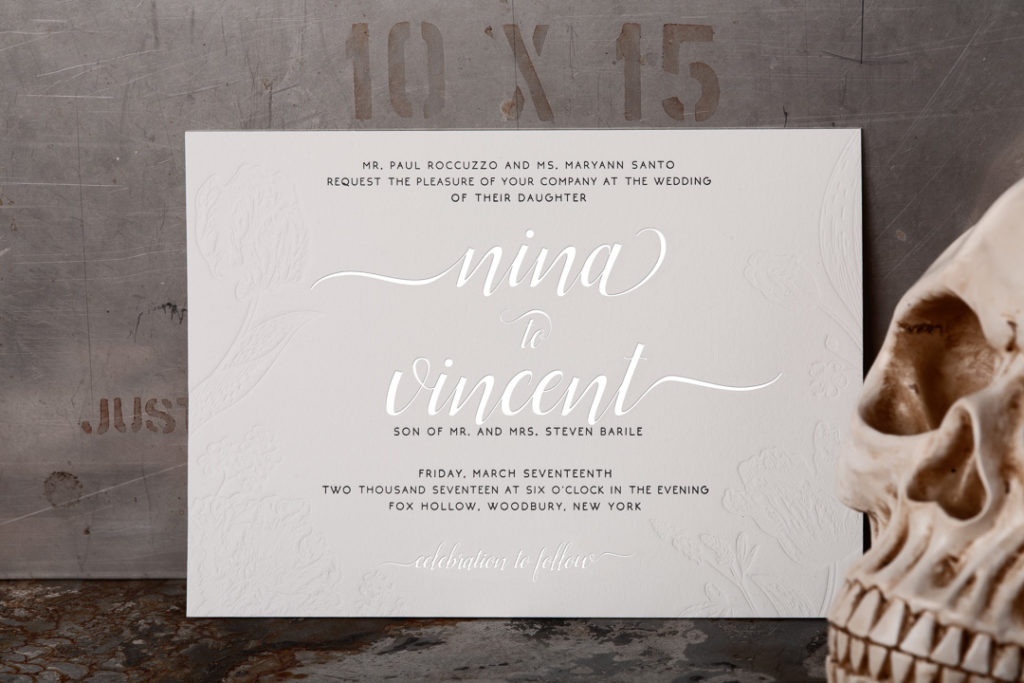

Can you print on very thick cardboard or museum board?

236-pound Reich Savoy and 220-pound Crane’s Lettra and the like are our daily bread, and we are able to double the thickness by laminating multiple sheets to each other, even differently colored stock. One of our machines is designed for extra thick cardboard.

Why do you use cotton rag paper?

Letterpress does exceptionally well with uncoated papers with a lot of volume… Soft cotton rag papers are perfect for letterpress and increase the tactile experience of the deboss, or punch, that we love so much.

Can you print on coated paper?

While this is possible with a kiss impression, we’d suggest to employ offset printing for better results.

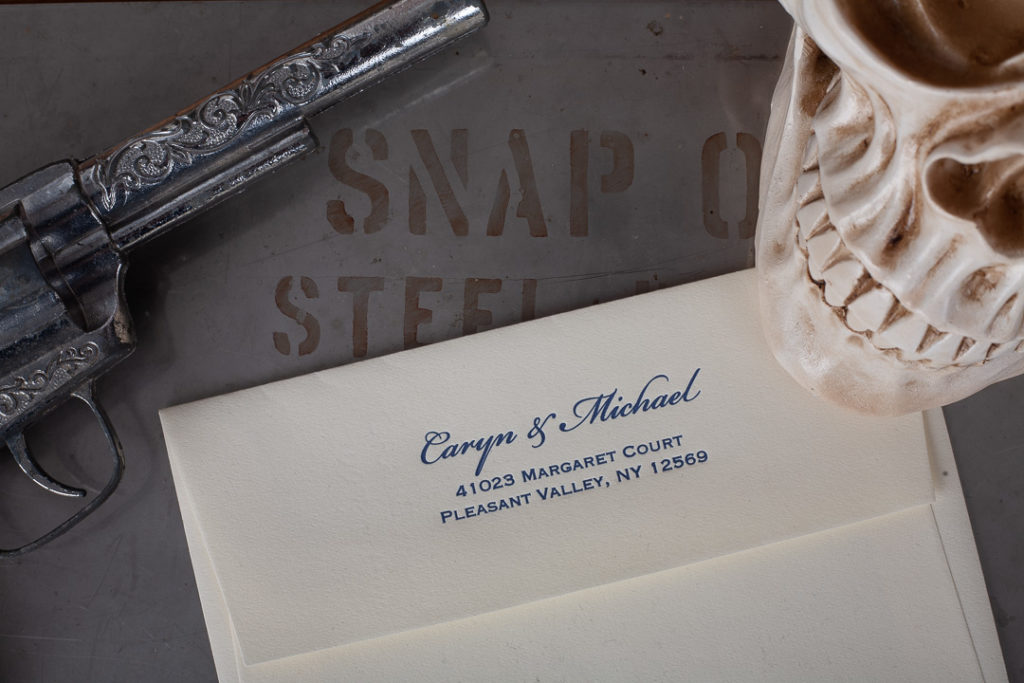

How big can a sheet be up to?

Our Heidelberg Windmills accommodate sheets up to 10″x15″ for small and large runs. Our hand cranked Poco proof press takes up to 12″x18″ sheets for small runs. The Vandercook SP-15 is good for a 14″x18″ sheet size.

What about colored paper?

Letterpress inks are always translucent and colored papers may not get the desired results. We can always run a proof on the desired stock, or mix inks accordingly.

Raghaus Studios Letterpress

Deep impressions for great people

Call toll free 888-859-3688

Click here to email us for letterpress inquiries or graphic design assistance

223 Broadway, Rear · Newburgh, New York